Concentric

Series SB71-A

Specifications

Concentric - Series SB71-A

Features & Benefits

-

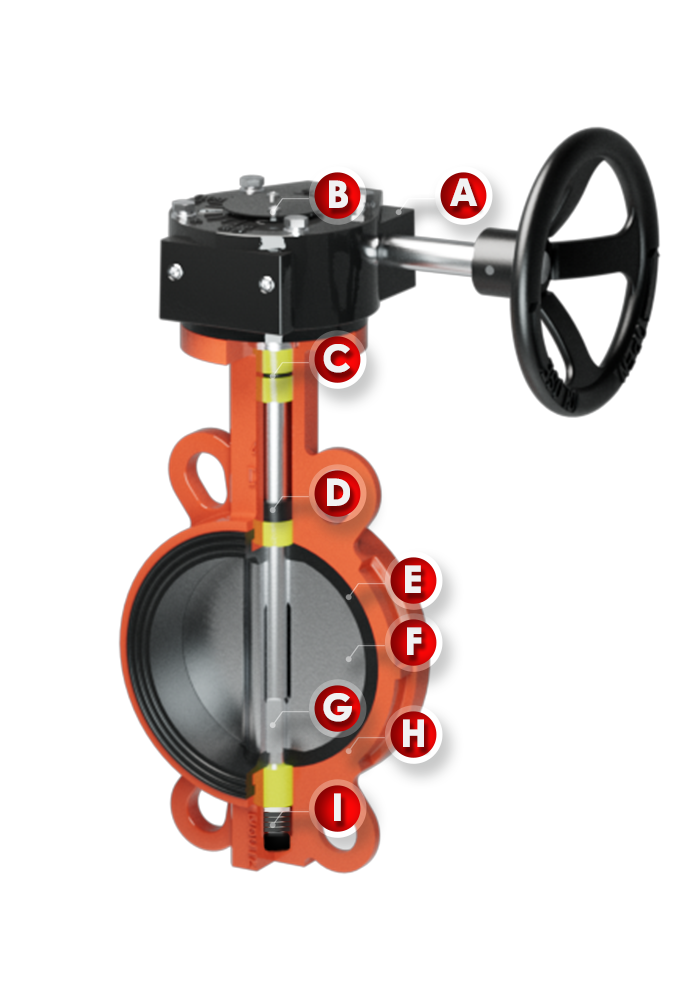

A. Gear Operation

According to the size and torque of the butterfly valve, with single-stage and two-stage turbines, it can be operated directly manually, or it can be connected to an actuator to achieve automated operation.The turbine box of IP67/68 can also be customized according to demand.

-

B. Position Indicator

The position indication device can be customized according to requirements: indication arrow, dial, limit switch with signal transmission and etc.

-

C. O Ring

O ring is used as stem seal, which can achieve interference fit and ensure tightness.

-

D. Bushing

It has the function of maintaining the position of the valve stem and can ensure the sealing between the valve stem and the valve body. And the material can be adapted to the medium.

-

E. Seat

It has zero leakage sealing and is replaceable & wear resistant. The material can be adapted to the medium. The soft rubber seat is easy to install and replace, and the widened flanging design makes it suitable for a variety of mating flanges. It has better sealing than the hard back seat. The larger the diameter is, the more obvious the advantages are. At the same time, the cost is only half of the hard back seat, so the soft rubber seat is the general trend of wafer concentric butterfly valves.

-

F. Disc

It has streamlined design, small resistance, large flow. Its material can be selected according to the medium, such as vulcanized rubber or fluoroplastics.

-

G. Hexagonal

It can transmit greater torque without pin fixing, ensure the surface of disc is smooth and more resistant to erosion and corrosion,facilitate the replacement of stem or disc, make disassembly and assembly more convenient.

-

H. Body

The soft back seat only matches its own body, the depression in the body is actually to give the seat more force support, so that the valve seat is not easy to shift and deform under pressure. In addition to its beautiful appearance, this body is also suitable for a variety of connection standards, such as PN10, PN16, CLASS 150, 5K, 10K, Table D, Table E and etc.

-

I. Additional Sealing & Multiple Insurance

The new structure can effectively prevent the problem of leakage at the upper & lower shaft holes of DN400-DN1200. User can just remove the bolts and bottom cover (circlip), and rotate the packing gland counterclockwise to compress the packing, make the packing more compact and full to increase the sealing from the stem. Customized tools can be provided for customers with the order. when there is no leakage, reinstall the parts back to the body