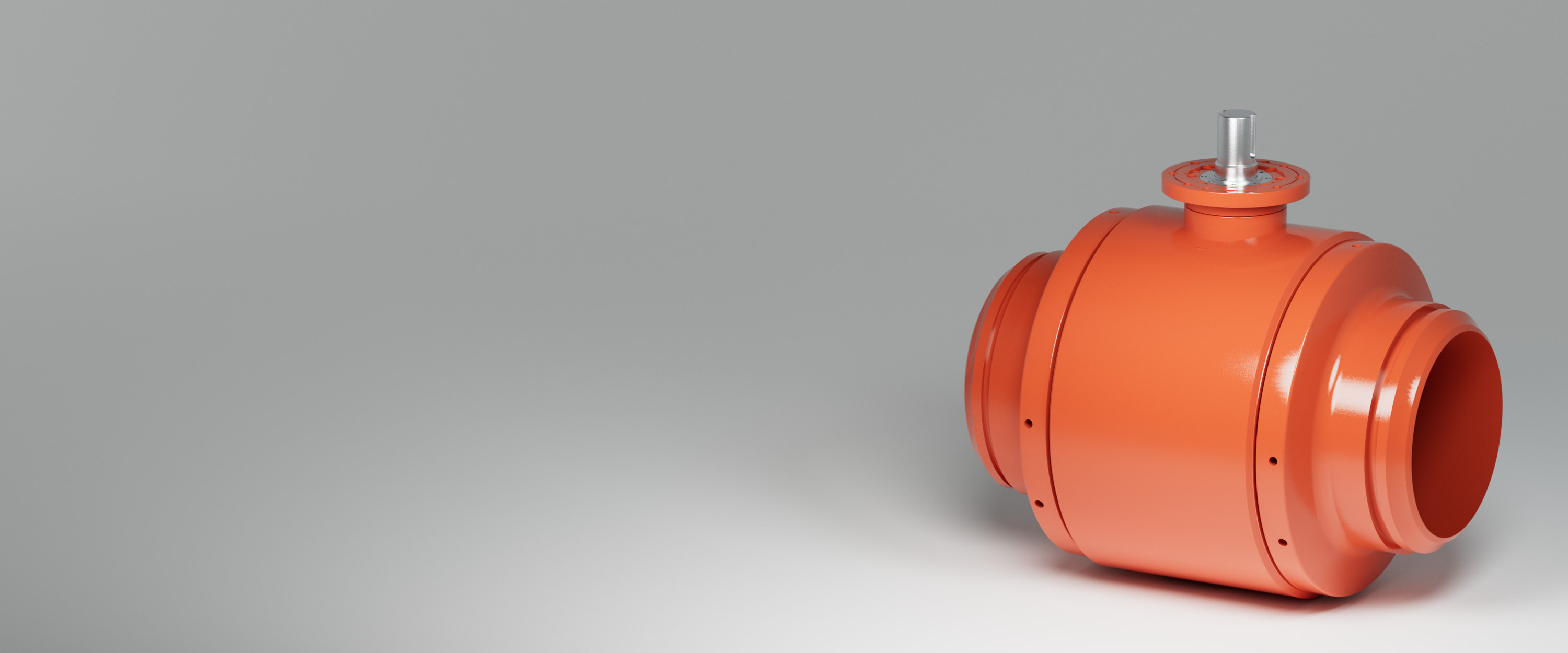

Fluroplastic Seated

Series SK61

Specifications

Fluroplastic Seated - Series SK61

Features & Benefits

-

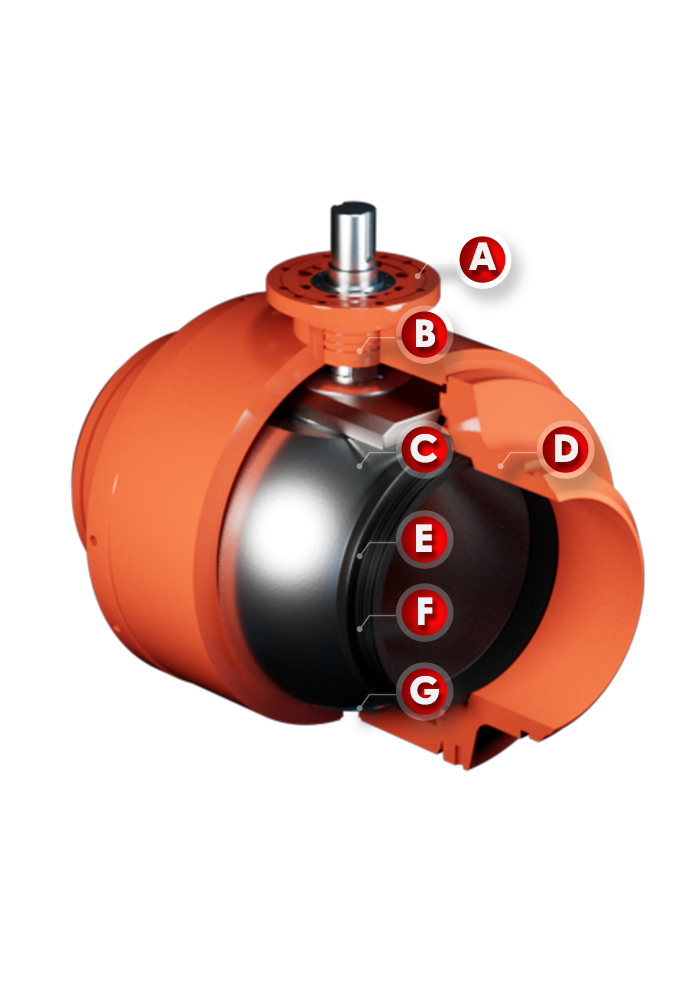

A. Connection

Yoke under actuator can be customized according to requirements., which allows to install electric/pneumatic actuators by different standards.

-

B. Packing

As a common packing material, flexible graphite is cheap, easy to replace and can bear high & low temperature.

-

C. Ball

It has good sealing performance with high precision grinding. Also, it can be hardened as required.

-

D. Body

The fully welded body is assembled and welded by 6-part forged shell components. The weight of the valve can be reduced by a quarter, much less than 3-piece structure. At the same time, it avoids the leakage of the flanges and bolts. The internal curve of the welded structure is smooth, which maintains the lubricating connection with the pipeline and provides good fluidity for medium.

-

E. Seat

Fluoroplastic seat can achieve complete sealing and zero leakage. The seat can be replaced, whose material can be selected according to the medium.

-

F. Seat Back

Viton and metal ring make the valve seat achieve sealing self-adjustment, which can achieve zero leakage between the ball and seat.

-

G. Stem

The large-diameter ball valve is supported by the lower stem, so that the ball is better fixed on the valve body. It ensures that there is no deflection in horizontal rotation, and the sealing surfaces of the ball and the valve seat fit each other.