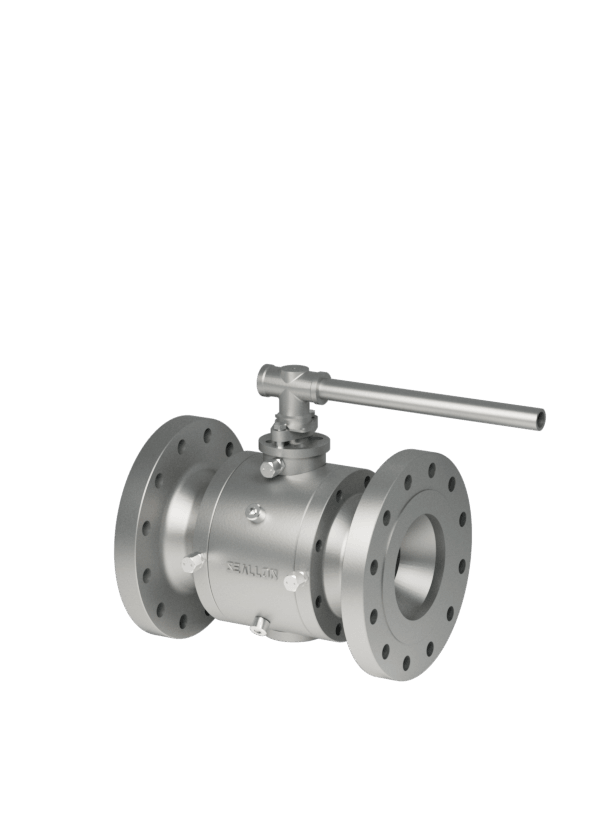

Metal Seated

Series SK41-M

Specifications

Metal Seated - Series SK41-M

Features & Benefits

-

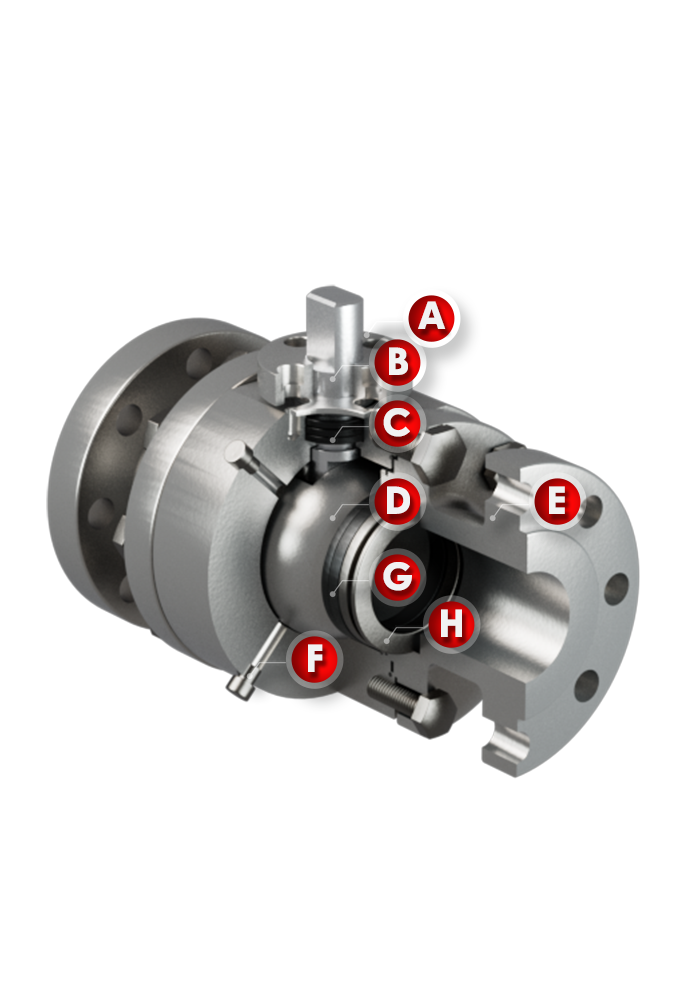

A. Top flange connection

High platform or yoke under actuator can be selected, which allows to install electric/pneumatic actuators by different standards.

-

B. Packing

PTFE (or reinforced graphite) packing material can effectively enhance the sealing from the stem, reduce the opening and closing torque, and make the operation more labor-saving.

-

C. Stem

The stem is internally installed, whose shoulder and PTFE (or reinforced graphite) thrust pad prevent the stem from blowing out due to the sudden increase of pressure in the pipeline. The fireproof and anti-static structure can be selected by request. And the conductive spring will be set between the stem & body and the stem & ball to avoid igniting flammable medium due to static electricity, ensuring system safety.

-

D. Ball

O-type floating ball adopts full-bore design, makes flow resistance small.

-

E. Body

The three-piece valve body structure makes the maintenance and disassembly of the valve easier and extends the service life of the valve.

-

F. Vent Valve

When the ball valve is closed, the pressure will accumulate in the valve body. By opening the vent valve to relieve the pressure, there will be a pressure difference between the inlet and outlet ends of the valve seat. The pressurized valve seat is easier to ensure the tightness.

-

G. Metal Seat

With high wear resistance and corrosion resistance, the hard metal-to-metal sealing seat can be applied to high temperature and high pressure medium. It also can be a dual protection of the fire-resistant structure.

-

H. Seat Back

Viton and metal ring make the valve seat achieve sealing self-adjustment, which can achieve zero leakage between the ball and seat.