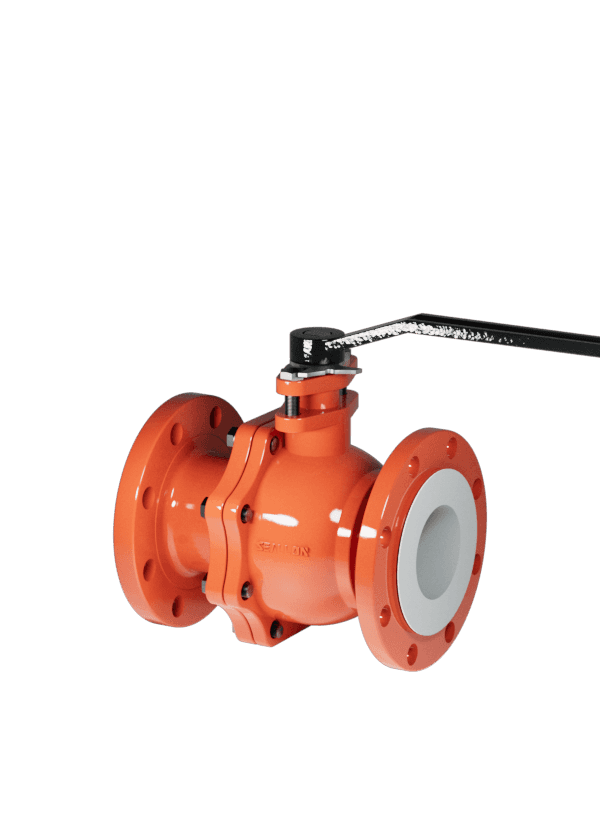

Fluroplastic Seated

Series SK41-P

Specifications

Fluroplastic Seated - Series SK41-P

Features & Benefits

-

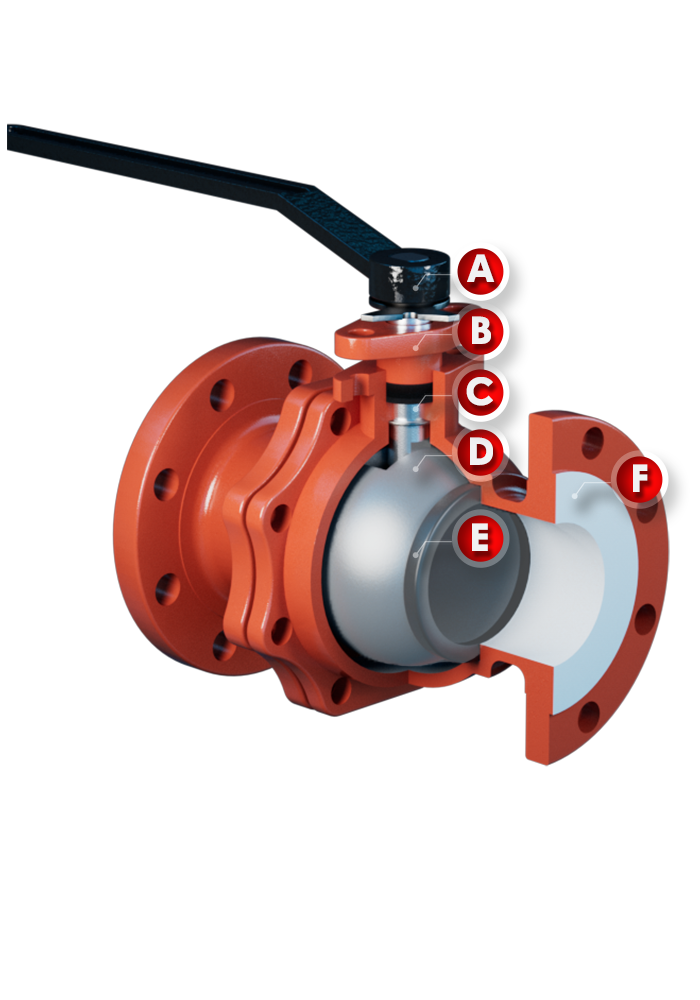

A. Handle

One-piece cast handle, easy to operate, quick to open and close. The top flange under actuator can also be customized according to customer requirements.

-

B. Gland

The gland effectively protects the internal packing, thus preventing the medium leaking out from the stem. Also, it can be opened and then the packing can be replaced in time to solve the problem of leakage from the stem.

-

C. Stem

The stem is internally installed, whose shoulder and PTFE (or PFA) thrust pad prevent the stem from blowing out due to the sudden increase of pressure in the pipeline.

-

D. Ball

The ball is coated with anticorrosive materials such as PTFE, PFA to avoid contact between the metal core and the medium, and it fits closely with the seat to ensure sealing and extend its service life.

-

E. Seat

Fluoroplastic seat can achieve complete sealing and zero leakage. The seat can be replaced, whose material can be selected according to the medium.

-

F. Body

The inside of body is covered with fluoroplastic, keeping zero contact with the medium, effectively enhancing the corrosion resistance. Two-piece structure is convenient to replace parts such as ball and seat. Different materials can be selected according to working conditions.