Fluroplastic Seated

Series SK11

Specifications

Fluroplastic Seated - Series SK11

Features & Benefits

-

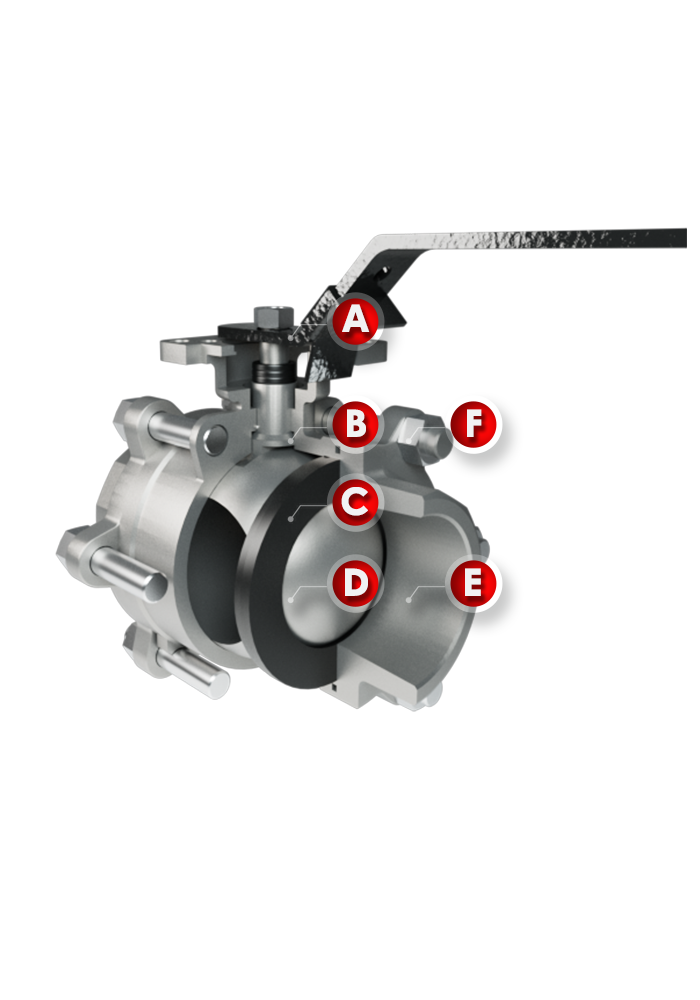

A. Handle

The forged one-piece handle has high strength and good toughness, extended design, and it’s more labor-saving to open the valve.

-

B. Upper Stem

The upper stem has a thrust design.

-

C. Seat

The seat material can be selected according to the medium such as PTFE, PPL, PEEK and etc.

-

D. Ball

Through high-precision processing and grinding, the ball has high hardness and is tightly connected with the valve seat, which has a good sealing performance.

-

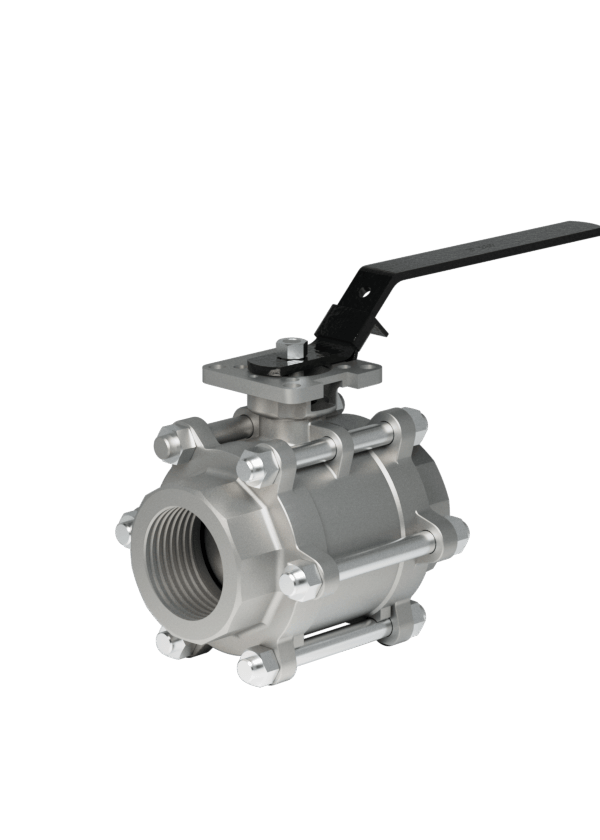

E. Body

Body material can be selected according to the medium and the platform under actuator can be customized according to customer requirements. The connection can be threaded, flanged and butt welded.

-

F. Structure

Three-piece detachable design allows the valve internals to be replaceable and extends the service life of the valve.