Standard Seal

Series SGL61-F

Specifications

Standard Seal - Series SGL61-F

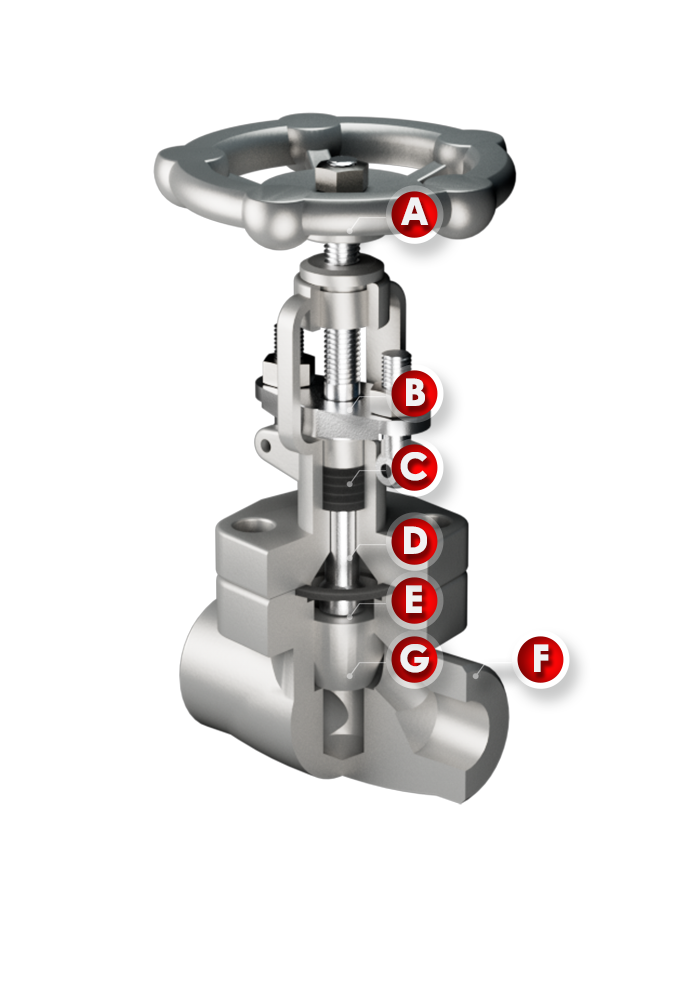

Features & Benefits

-

A. Handwheel

Its material is forged steel as same as the valve body, which is more durable and allows to be opened and closed thousands of times without deformation.

-

B. Gland

The gland effectively protects the internal packing, thus preventing the medium from leaking out from the stem.

-

C. Packing

As a common packing material, flexible graphite is cheap, easy to replace and can bear high & low temperature.

-

D. Stem

Different materials can be selected according to working conditions.

-

E. Disc

The conical disc has good sealing performance. Its conical sealing surface is relatively less damaged by medium’s sediment. And it can be surfacing welding Stellite and etc.

-

F. Body

The forged body has a smooth surface, high pressure resistance, excellent corrosion resistance, better plasticity and toughness than the cast body, and a longer service life.

-

G. Seat

The seat can be surfacing welding Stellite and etc.