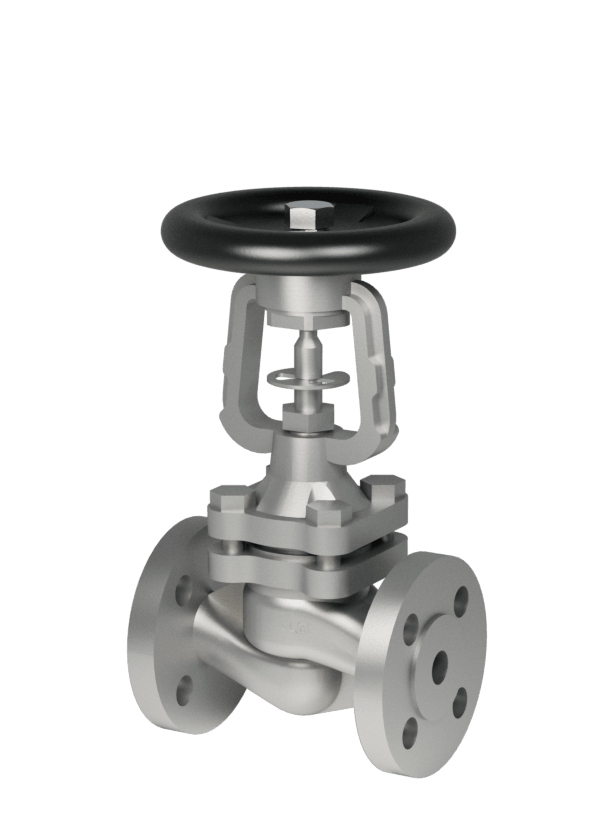

Bellows Seal

Series SGL41-B

Specifications

Bellows Seal - Series SGL41-B

Features & Benefits

-

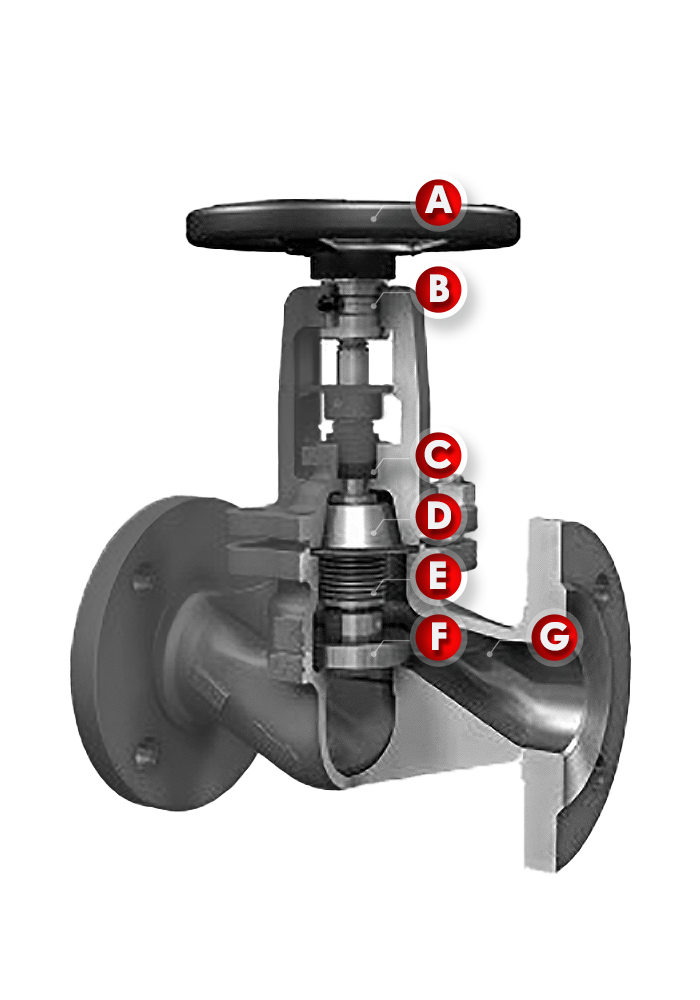

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving. The steel material can also be an economical option.

-

B. Stem Bushing

The stem bushing acts as a support for the handwheel and drives the stem to rotate through the internal thread to lift the disc. Bronze and steel can be selected by requirements.

-

C. Packing

Reinforced graphite packing material can effectively enhance the sealing from the stem, reduce the opening and closing torque, and make the operation more labor-saving.

-

D. Bellow Seal

Double seal is used. Under high temperature conditions, the stem does not contact with the medium for zero leakage. Meanwhile, sufficient strength and toughness are guaranteed, and it can be opened and closed tens of thousands of times.

-

E. Bellow

High-performance elastic metal bellows have a particularly long telescopic fatigue life. It completely eliminates the disadvantages of fast aging and easy leakage of ordinary stem packing seals.

-

F. Disc

The sealing surface is flat or conical, and the disc moves linearly along the center line of the fluid. During the opening and closing process, the friction between the sealing surfaces is small, which is relatively durable. The opening height is not large. It is suitable for high pressure.

-

G. Body

There is no fluid loss, reducing energy loss and improving the safety of factory equipment.