Standard Seal

Series SGL41

Specifications

Standard Seal - Series SGL41

Features & Benefits

-

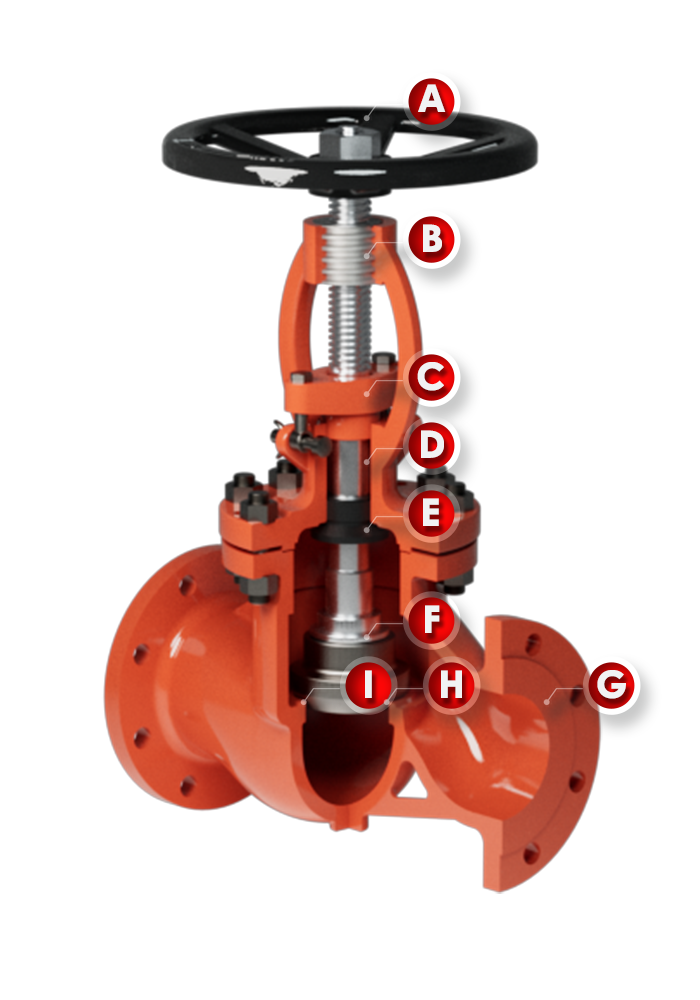

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Stem Bushing

The stem bushing acts as a support for the handwheel and drives the stem to rotate through the internal thread to lift the disc. Bronze and steel can be selected by requirements.

-

C. Gland

The gland effectively protects the internal packing, thus preventing the medium leaking out from the stem. Also, it can be opened and then the packing can be replaced in time to solve the problem of leakage from the stem.

-

D. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

E. Packing

As a common packing material, flexible graphite is cheap, easy to replace and can bear high & low temperature.

-

F. Disc

The conical seal surface narrows the contact surface. Under a certain pressure, the force ratio of the sealing surface increases. Compared with the flat seal, the damage to conical seal casued by solid particles and medium sediments is relatively small.

-

G. Body

A variety of materials can be selected, and it has a self-sealing structure.

-

H. Disc Sealing

Conical-shaped sealing can be surfacing welding alloy steel.

-

I. Seat

The hard metal-to-metal sealing seat can be applied to high temperature and high pressure medium. The seat can be surfacing welding alloy steel or other materials with high wear resistance and corrosion resistance.