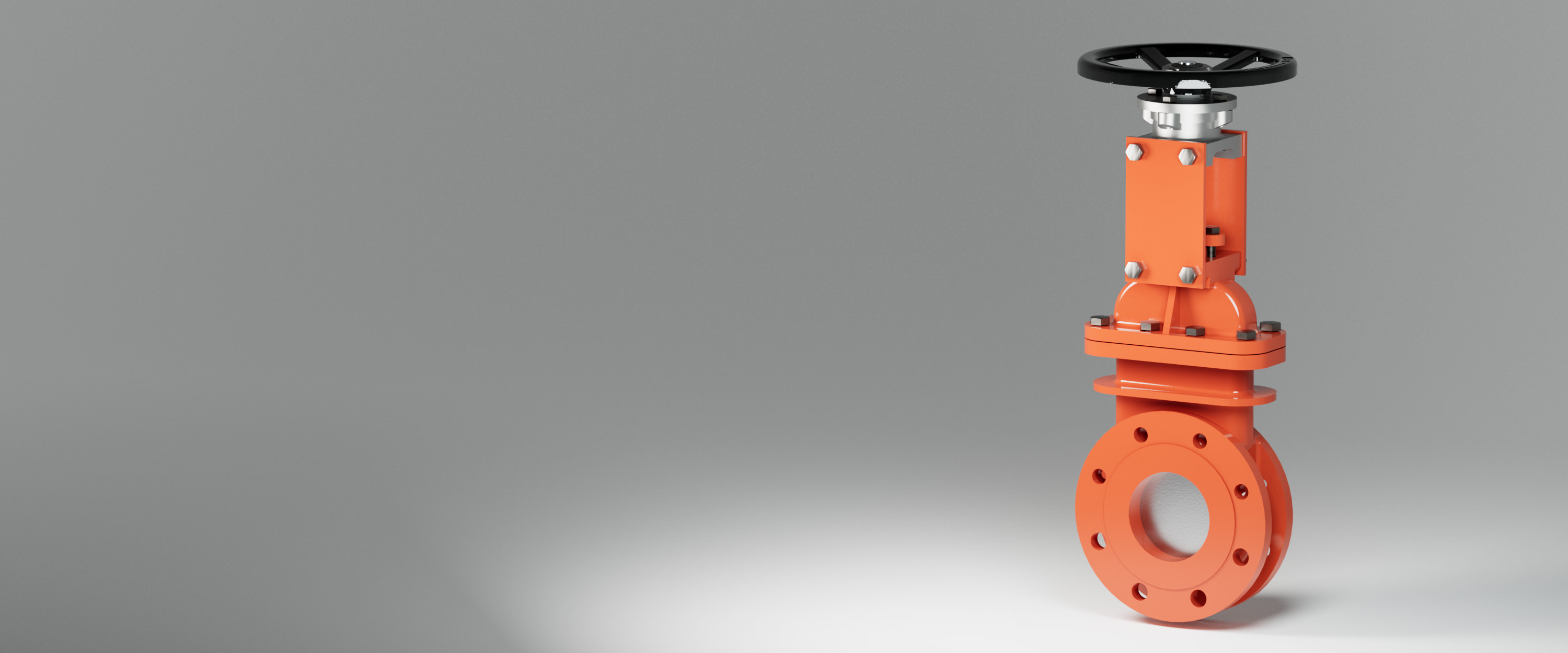

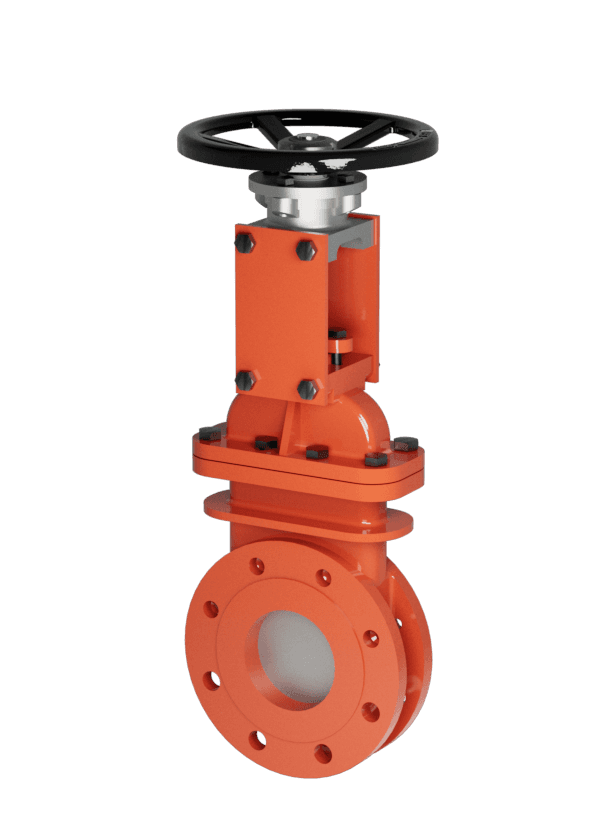

Knife Gate Valve

Series SG73-E

Specifications

Knife Gate Valve - Series SG73-E

Features & Benefits

-

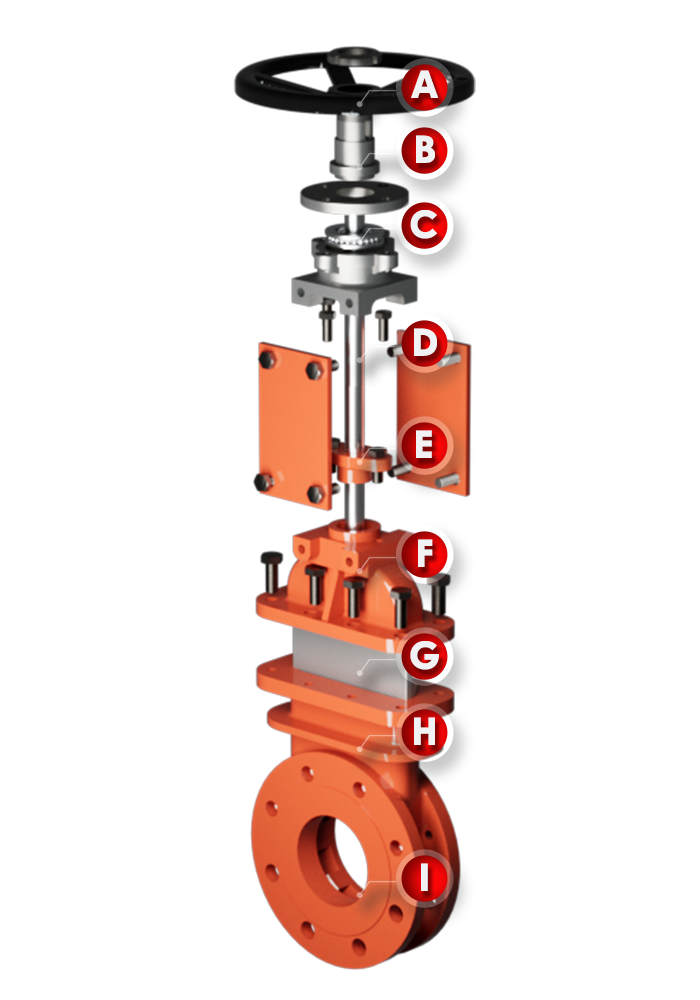

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Stem Bushing

The stem bushing acts as a support for the handwheel and drives the stem to rotate through the internal thread to lift the disc. Bronze and steel can be selected by requirements.

-

C. Bearing

Bearing can be selected for the big size of knife gate valve to reduce the opening & closing torque.

-

D. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

E. Gland

The gland effectively protects the internal packing, thus preventing the medium leaking out from the stem. Also, it can be opened and then the packing can be replaced in time to solve the problem of leakage from the stem.

-

F. Cover&Body

The design of the body and cover greatly improves the overall pressure bearing capacity of the valve, ensuring that the packing is well sealed and there is no leakage in the high-pressure pipeline.

-

G. Disc

In order to cope with higher pressure, the disc can be thickened by requirements.

-

H. Body

The thickness of the body is thicker than that of ordinary knife gate valves, and there are multiple reinforcement designs that can withstand higher pipeline pressure.

-

I. Seat

Resilient seat and metal seat can be selected according to the medium.