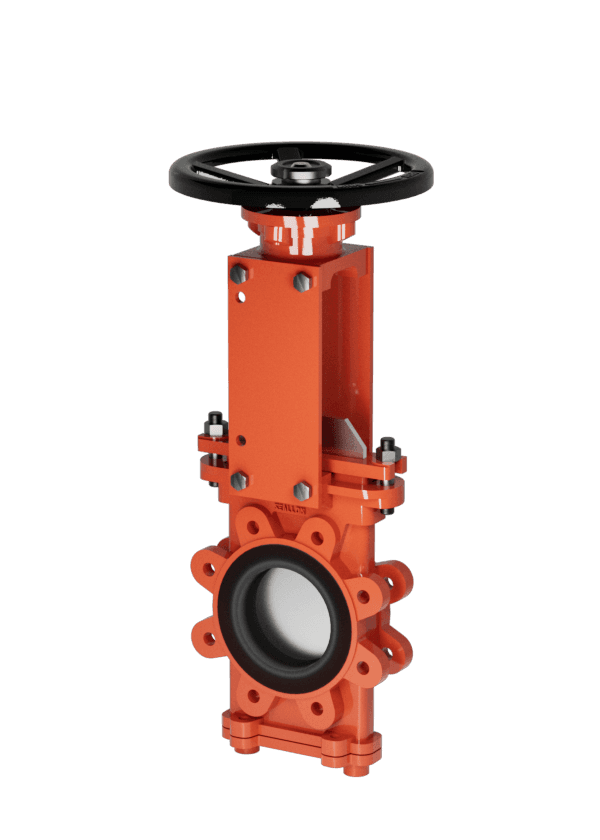

Knife Gate Valve

Series SG73-D

Specifications

Knife Gate Valve - Series SG73-D

Features & Benefits

-

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Stem Bushing

The stem bushing acts as a support for the handwheel and drives the stem to rotate through the internal thread to lift the disc. Bronze and steel can be selected by requirements.

-

C. Bearing

Bearing can be selected for the big size of knife gate valve to reduce the opening & closing torque.

-

D. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

E. Packing

Rubber and nylon packing material can effectively enhance the sealing between the gland and disc. Different materials can be selected according to the medium.

-

F. Body

There is no groove in the flow channel of the body, so the medium will not get stuck and clogged. And it has the characteristics of full-diameter flow, which is suitable for the pipeline of powder granular medium. Different materials can be selected according to the working condition. Two-piece structure is available as requested.

-

G. Disc

The lower end of the disc is processed to be thin and sharp, which is easy to cut off viscous medium such as mud and pulp.

-

H. Seat

The bidirectional thickened rubber seats not only have sufficient sealing, but also is very wear-resistant, suitable for medium with corrosion.

-

I. Bottom Cover

The design of the bottom cover can enable the disc to bring out the dirt in the pipeline and clean up the inside of the body in time.