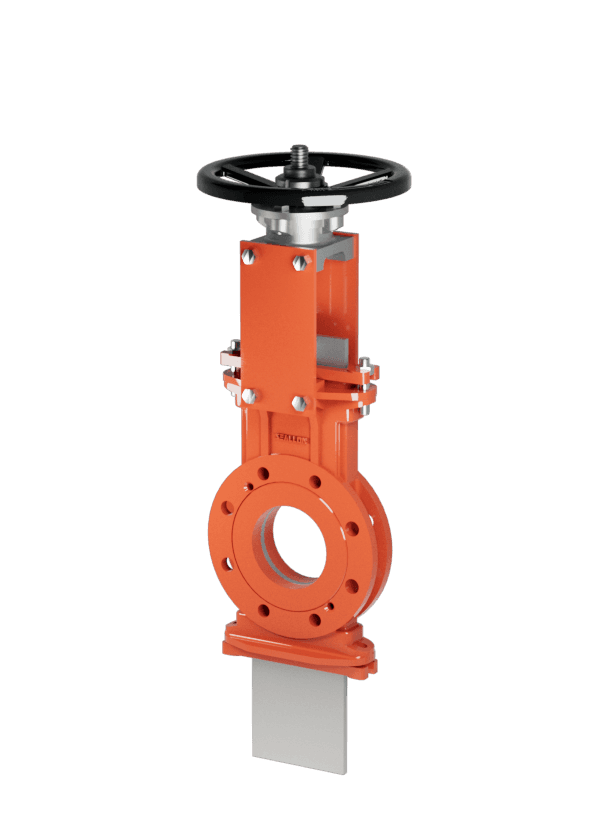

Knife Gate Valve

Series SG73-C

Specifications

Knife Gate Valve - Series SG73-C

Features & Benefits

-

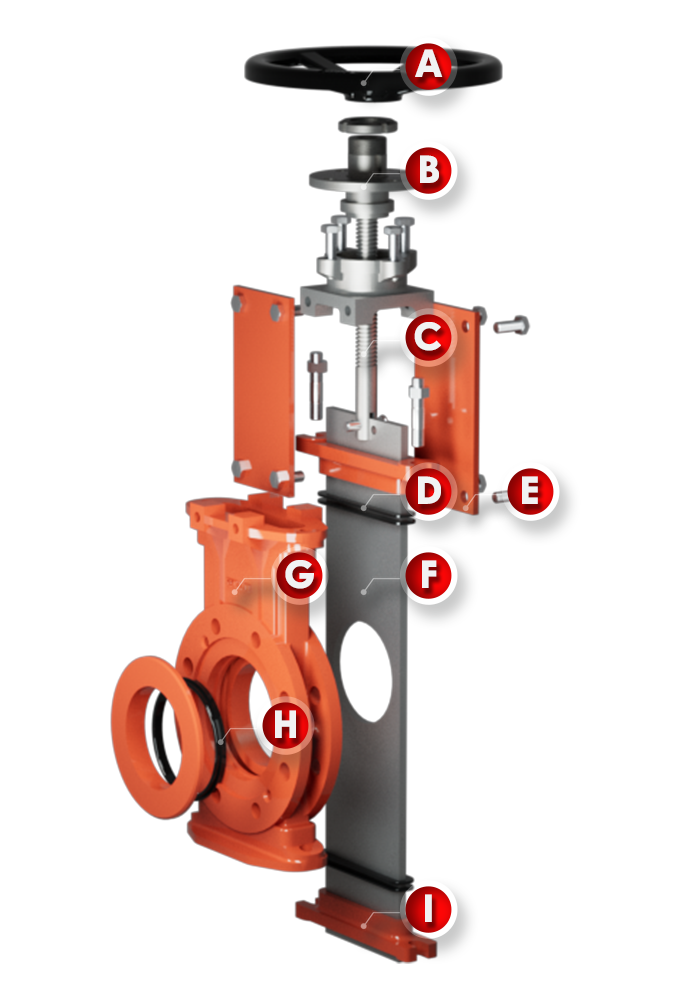

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Connection

Platform under actuator can be customized according to requirements., which allows to install electric/pneumatic actuators by different standards.

-

C. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

D. Packing

Rubber and nylon packing material can effectively enhance the sealing between the gland and disc. Different materials can be selected according to the medium.

-

E. Yoke

The yoke is composed of thickened steel plates, which is enough to support the disc, platform, and actuator.

-

F. Disc

There is a round hole on the disc, and its size is as same as the bore. Through the opening and closing of the disc, the round hole on the disc is completely detached from and coincides with the flow channel of the body, and it has the characteristic of cutting off viscous medium.

-

G. Body

There is no groove in the flow channel of the body, so the medium will not get stuck and clogged. And it has the characteristics of full-diameter flow, which is suitable for the pipeline of powder granular medium. Different materials can be selected according to the working condition. Two-piece structure is available as requested.

-

H. Seat

The seat is designed as a replaceable structure, which has anti-wear and automatic compensation functions, so it has a longer life span. During the opening and closing process of the disc, the seat is close to the disc to ensure stable opening and closing, and the viscous medium can also be scraped off.

-

I. Bottom Cover

The design of the bottom cover can enable the disc to bring out the dirt in the pipeline and clean up the inside of the body in time.