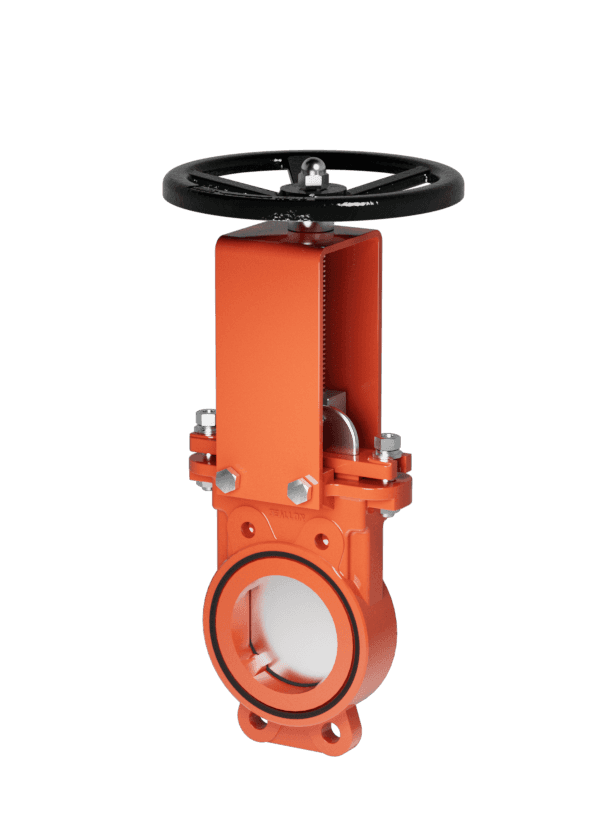

Knife Gate Valve

Series SG73-A

Specifications

Knife Gate Valve - Series SG73-A

Features & Benefits

-

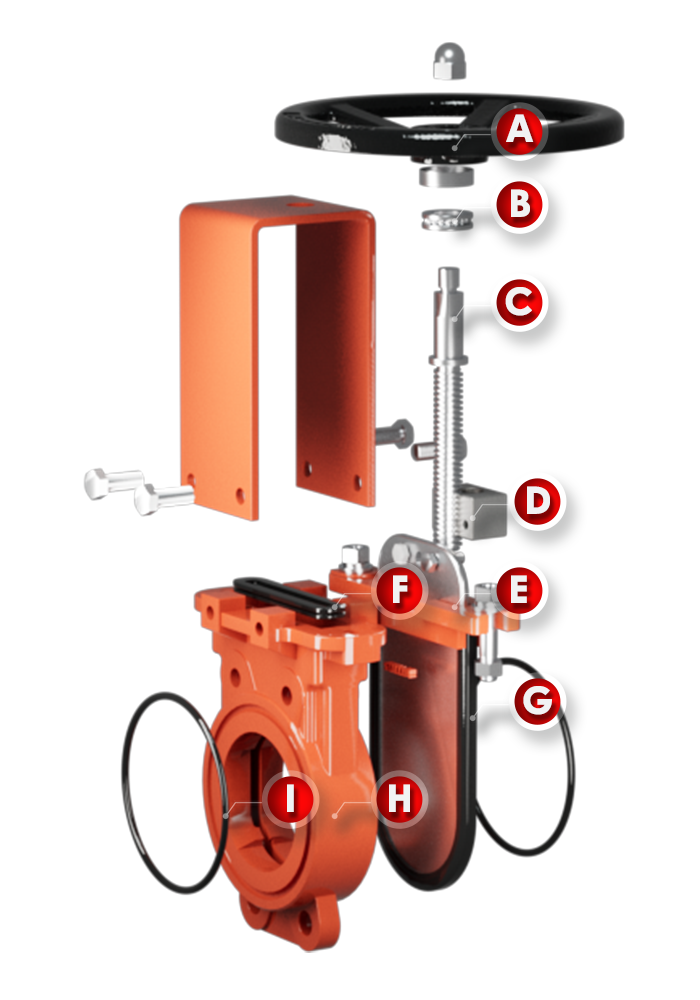

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Bearing

Bearing can be selected for the big size of knife gate valve to reduce the opening & closing torque.

-

C. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

D. Stem Nut

The stem nut is designed for the non-rising stem, and the opening and closing of the valve is not limited by space. It is the connection point between the stem and disc, so its wear resistance and corrosion resistance are the primary factors for material selection.

-

E. Disc

The polishing and chamfering design of the disc does not damage the seat. Different materials can be selected according to the medium.

-

F. Packing

Rubber and nylon packing material can effectively enhance the sealing between the gland and disc. Different materials can be selected according to the medium.

-

G. Seat

U-shaped valve seat is bidirectionally sealed, and can be replaced in case of damage. Different materials can be selected according to the medium.

-

H. Body

The body is one-piece structure with wafer or lug style. Polyester is coated for excellent corrosion resistance. Shorter length greatly reduces production and maintenance costs of the valve.

-

I. O Ring

Both-side O ring design makes the valve suitable for most of flanges in the market, easy to install, and greatly reduces the leakage between the valve and the mating flanges.