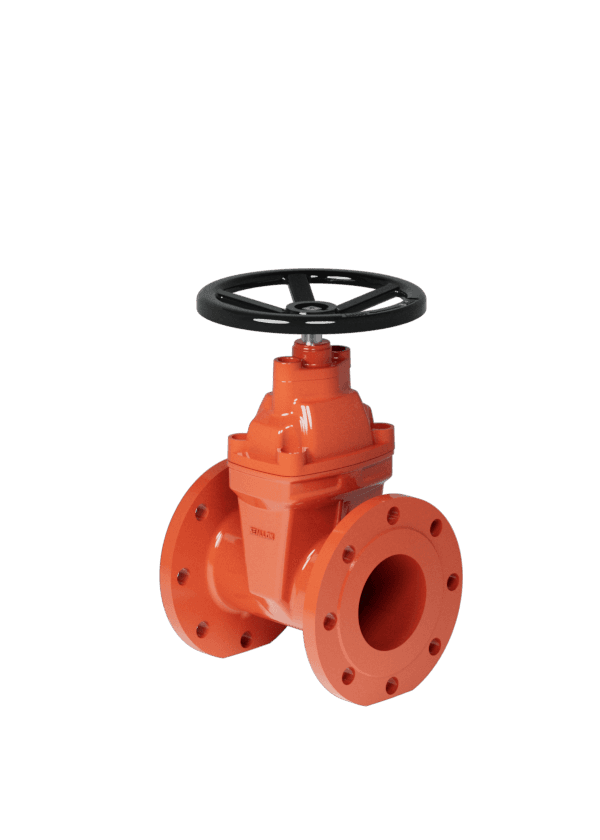

Resilient Seated

Series SG45

Specifications

Resilient Seated - Series SG45

Features & Benefits

-

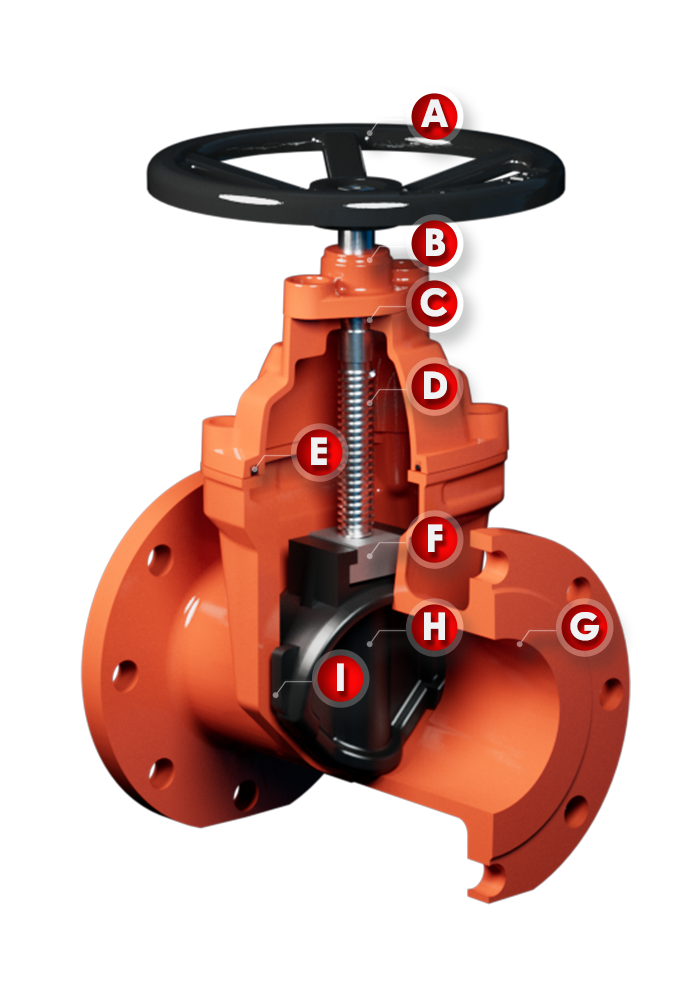

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Gland

The gland effectively protects the internal packing, thus preventing the medium leaking out from the stem. Also, it can be opened and then the packing can be replaced in time to solve the problem of leakage from the stem.

-

C. O Ring

O ring is also used as stem seal, interference fit, and ensure tightness.

-

D. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

E. Pad

The rubber pad ensures the sealing between the cover and body. Different materials can be selected by requirements.

-

F. Stem Nut

The stem nut is the connection point between the stem and disc, and its wear resistance and corrosion resistance are the primary factors for material selection.

-

G. Body

One-piece structure, more reliable reinforced body and better pressure bearing capacity. The coating of body is epoxy powder with the thicknessof more than 250 microns.

-

H. Disc

The whole resilient disc is covered with rubber, which has high sealing performance. Different materials can be selected according to the medium. The internal thread is combined with the stem, and the upper end is inlaid with the stem nut, so that the disc is not easy to fall off.

-

I. Positioned Block

In conjunction with the upper rail groove of the body, the disc is always opened and closed vertically up and down to avoid the shift caused by the pipeline pressure and lose sealing.