Metal Seated

Series SG41

Specifications

Metal Seated - Series SG41

Features & Benefits

-

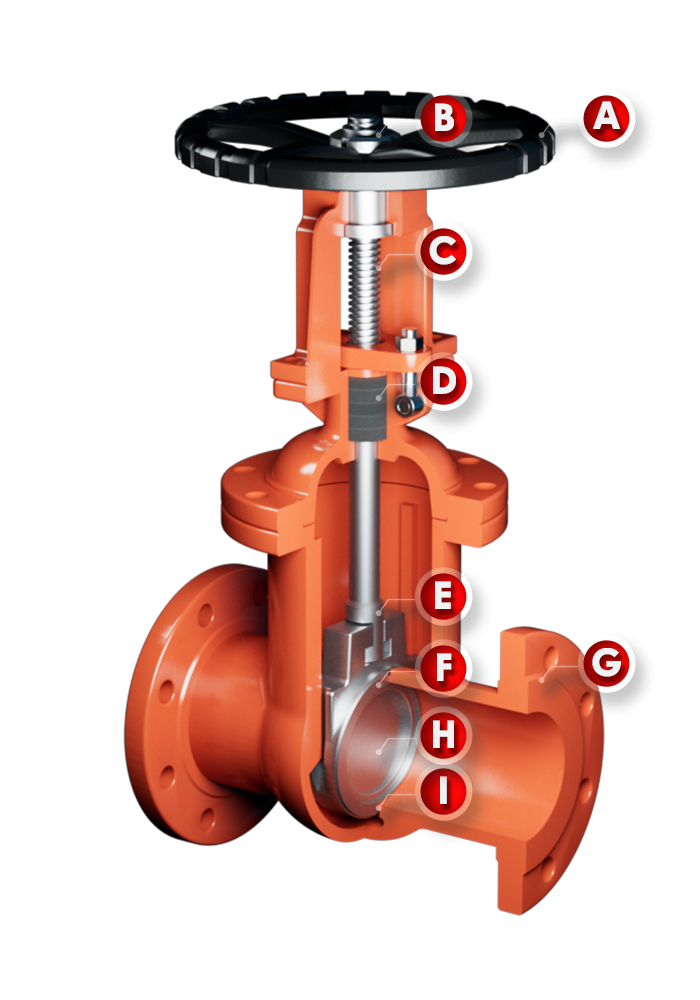

A. Handwheel

The ductile iron handwheel is more durable. The right size makes the handwheel rotate more labor-saving.

-

B. Stem Bushing

The stem bushing acts as a support for the handwheel and drives the stem to rotate through the internal thread to lift the disc. Bronze and steel can be selected by requirements.

-

C. Stem

Different materials can be selected according to the working conditions. Hardness and corrosion resistance are the primary considerations.

-

D. Packing

Reinforced graphite packing material can effectively enhance the sealing performance of the stem, reduce the openning & closing toque and make the operation more labor-saving.

-

E. Stem nut

As the connection point connecting stem and disc, wear resistance and corrosion resistance are the primary factors in material selection.

-

F. Disc Sealing

It is wedge-shaped and can be surfacing welding alloy steel.

-

G. Body

A variety of body materials can be selected. The body has a self-sealing structure, and its groove design plays the role of maintaining the disc, making the disc not easy to deform.

-

H. Disc

The disc is made of pure metal with high temperature resistance, high processing precision, wear resistance, and the disc does not block the flow channel when fully opened.

-

I. Seat

The hard metal-to-metal sealing seat can be applied to high temperature and high pressure medium. The seat can be surfacing welding alloy steel or other materials with high wear resistance and corrosion resistance.