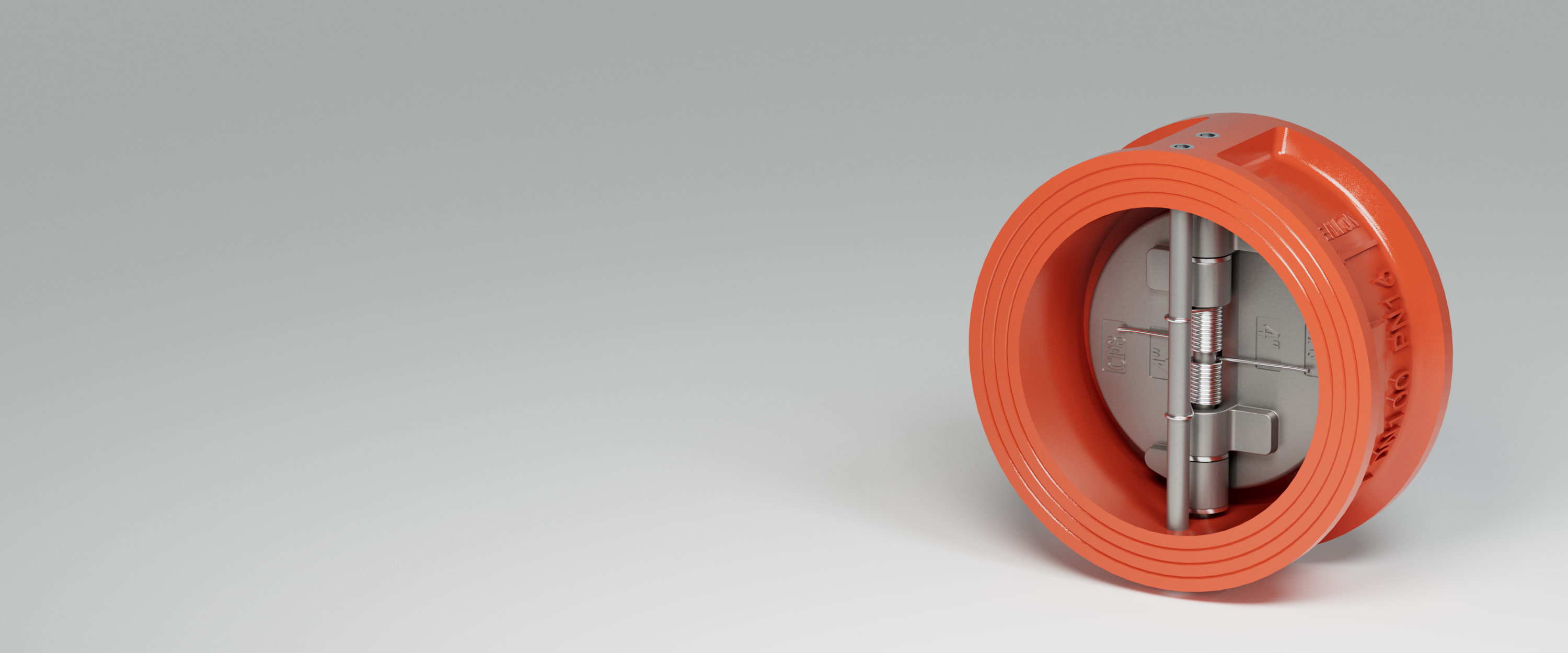

Double-Disc

Series SC77

Specifications

Double-Disc - Series SC77

Features & Benefits

-

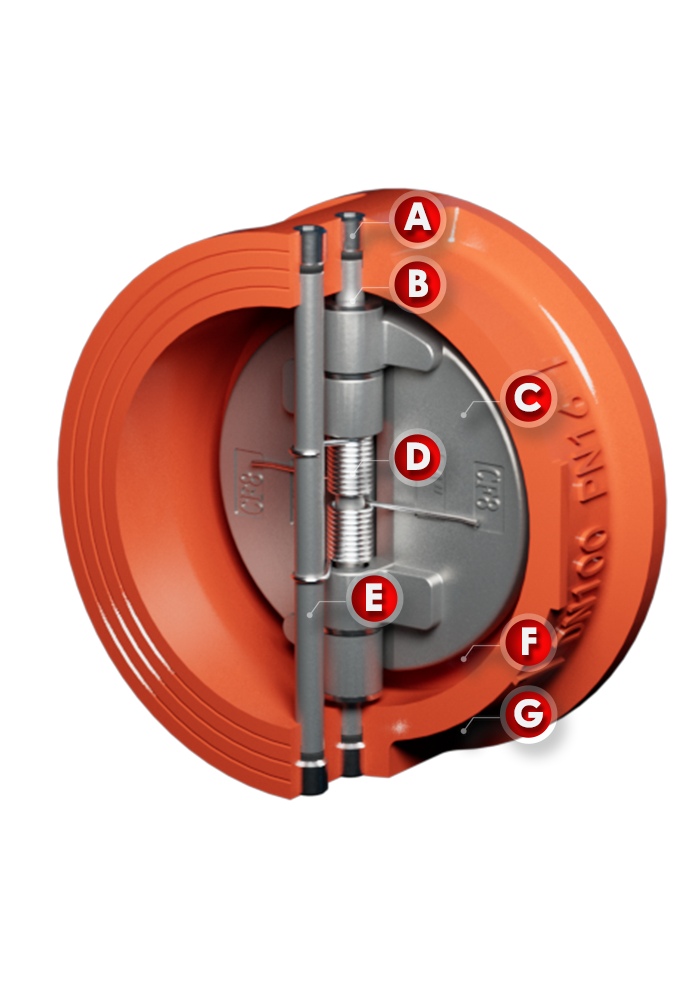

A. Bolt

The bolts fix the position of stem, which can be made of stainless steel.

-

B. Washer

The washers fix the position of disc and stem, ensuring the opening and closing of disc normally.

-

C. Disc

Fast repsonse and low flow resistance. Under the pressure of the pipeline, double- disc opens at the same time.

-

D. Spring

The discs are closed under the spring force, so that the installation position of the valve is not limited. The valve can be installed horizontally or vertically.

-

E. Stem

The stem not only supports the disc, but also limits the maximum opening of the discs to avoid damage caused by collision.

-

F. Seat

Rubber and metal seat can be selected according to the medium. The rubber seat can achieve zero leakage.

-

G. Body

Prevent water hammer impact. Zero noise and vibration. The compact volume greatly reduces the production cost of the check valve and facilitates installation and maintenance.