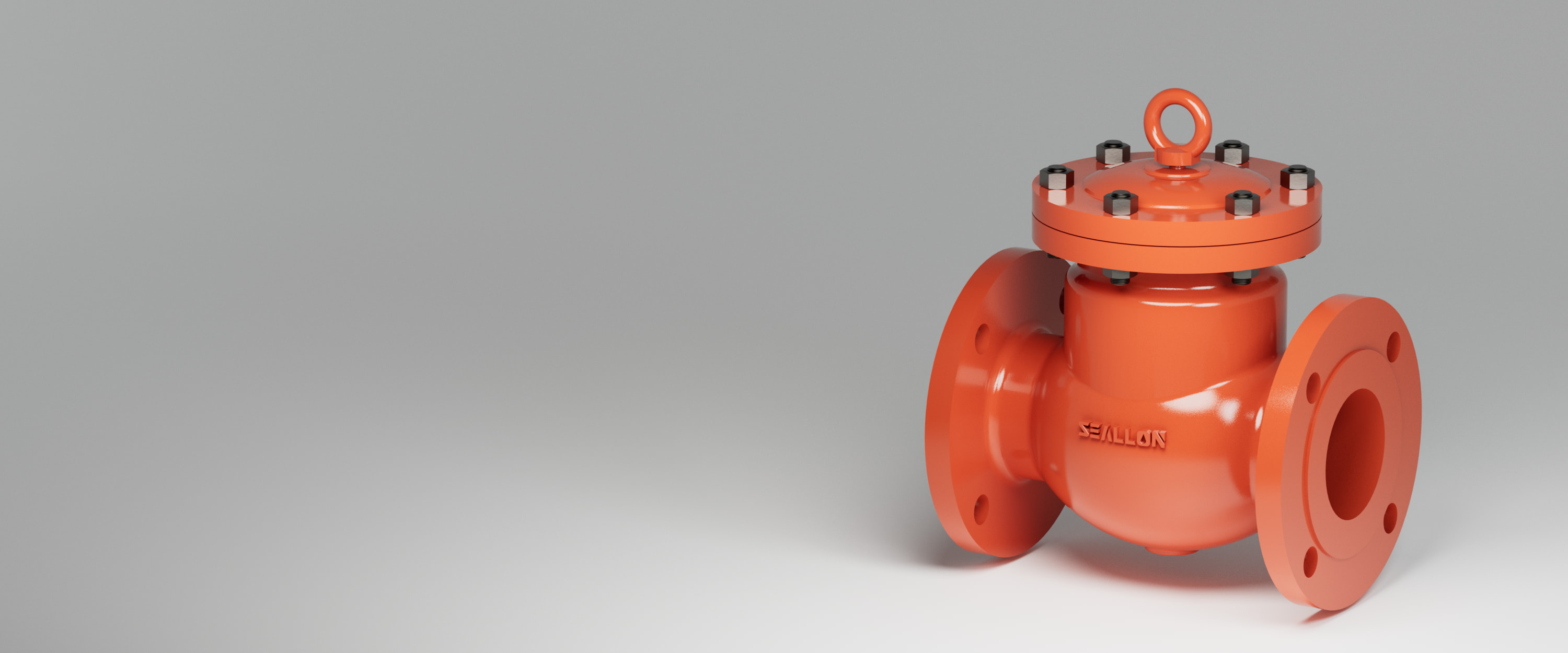

Swing

Series SC44

Specifications

Swing - Series SC44

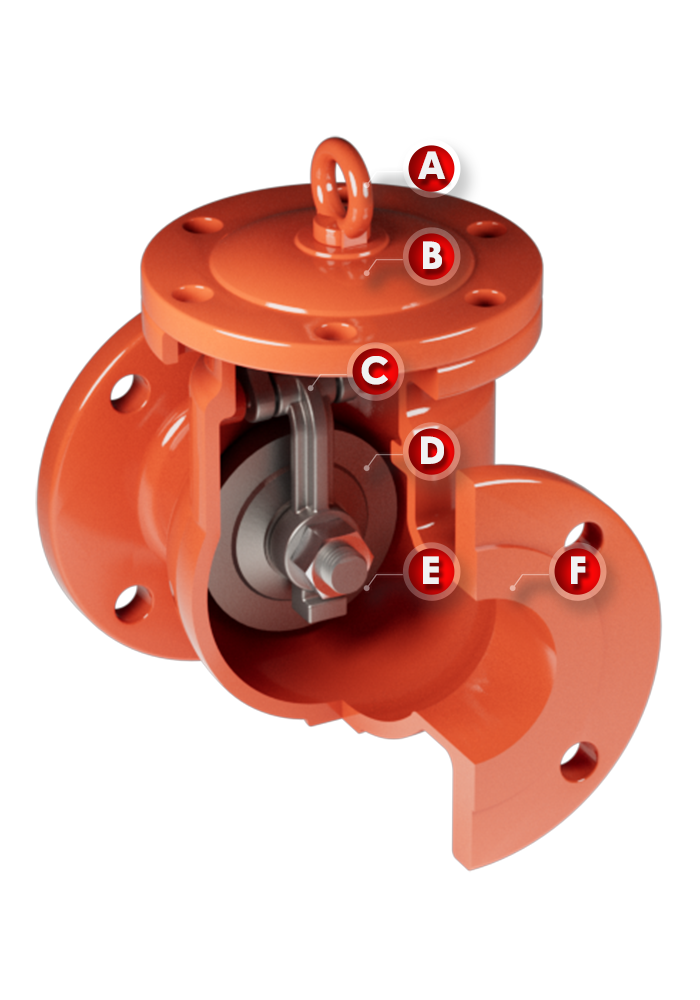

Features & Benefits

-

A. Hanging Ring

It is convenient to move and install.

-

B. Cover

By opening the valve cover, it’s easy to replace the internal parts of the valve, such as the disc, stem and etc.

-

C. Arm

The arm is the connection point between the stem and disc, and its wear resistance and corrosion resistance are the primary factors for material selection.

-

D. Disc

The disc is made of pure metal, which features high temperature resistance, high processing precision, wear resistance. And after the disc swings up, it has little influence on the flow of the pipeline.

-

E. Seat

The hard metal-to-metal sealing seat can be applied to high temperature and high pressure medium. The seat can be surfacing welding alloy steel or other materials with high wear resistance and corrosion resistance.

-

F. Body

A variety of materials are available. It is more suitable for horizontal installation and large diameters.