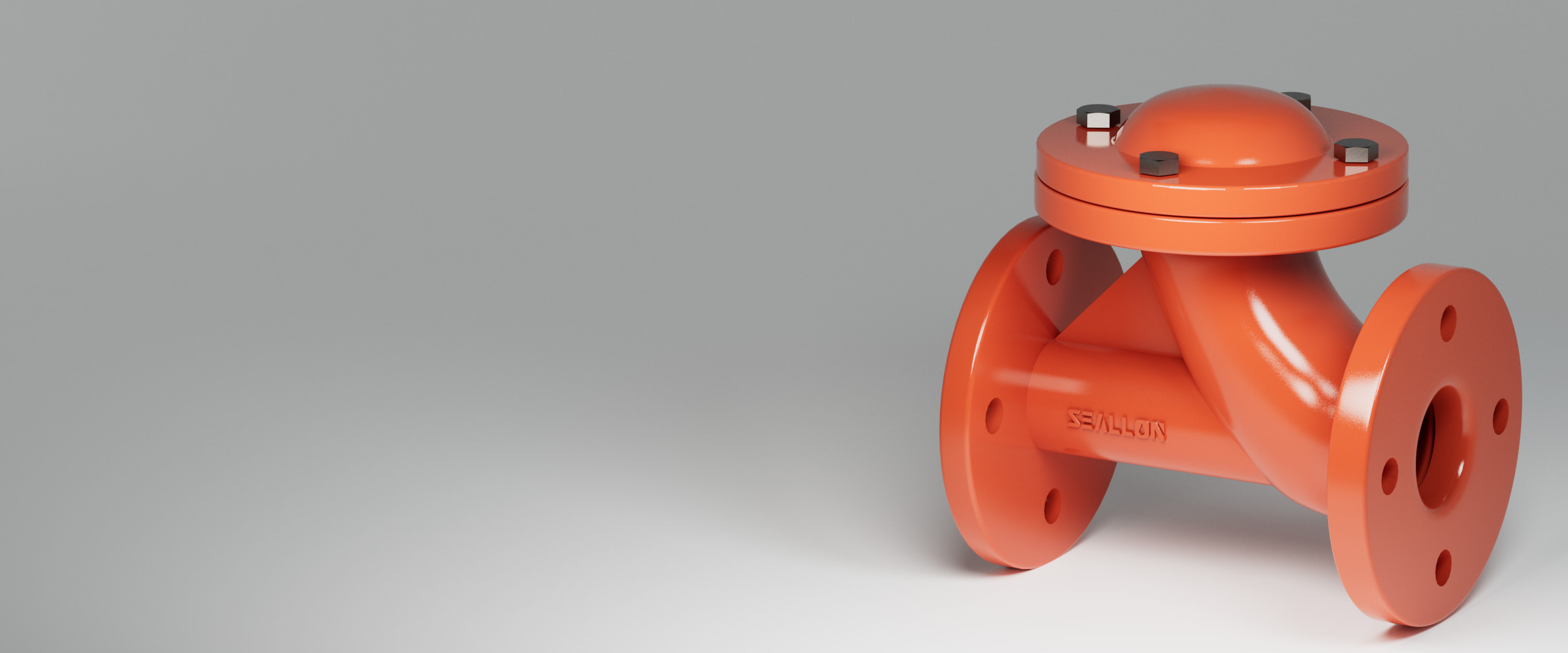

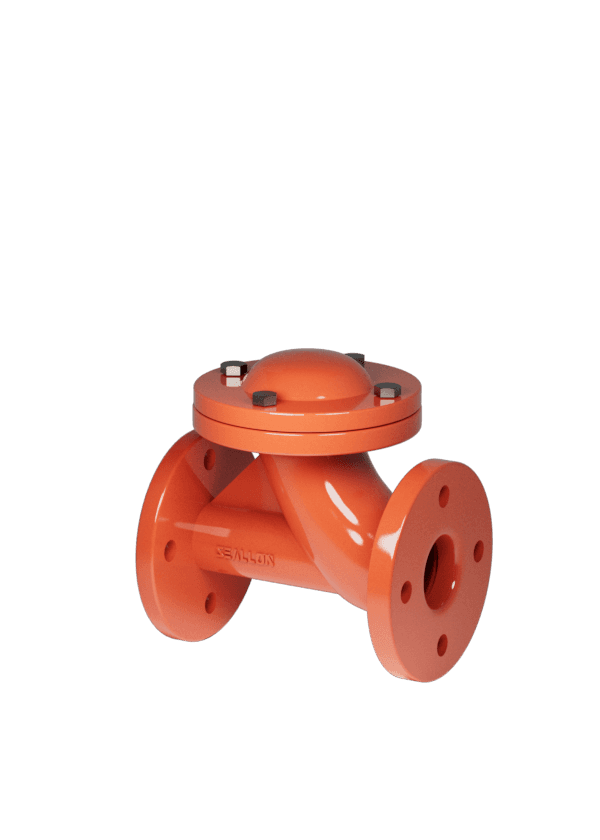

Lifting

Series SC41

Specifications

Lifting - Series SC41

Features & Benefits

-

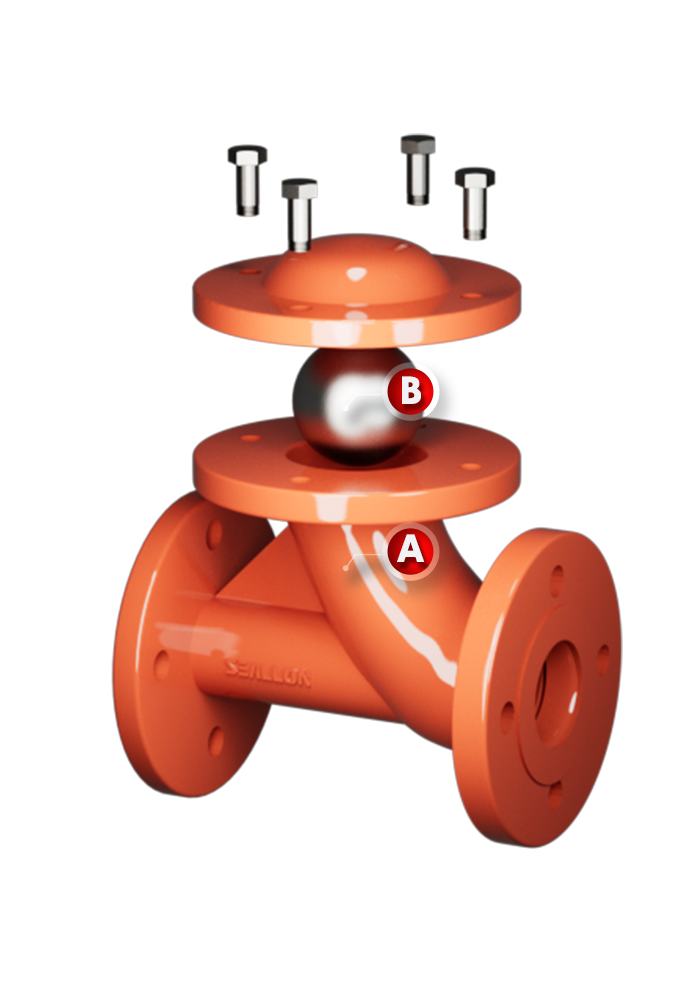

A. Body

The ball check valve is a check valve with multi-channel and multi-cone inverted fluid structure.

-

B. Ball

It adopts hollow steel ball with rubber. The rubber with good elasticity can not only ensure sealing, but also reduce the damage to the pipeline system during valve closing.

-

C. Structure

When the valve is opened, the conical body with holes can fix the steel ball, eliminating the pressure on the contact area between the rubber ball and the conical body. It is surface contact that reduces the hydraulic loss caused by the vibration of the rubber ball in the valve body.

-

D. Advantages

Stable operation, good sealing performance, long service life, low resistance coefficient and good shock absorption effect. Saving energy and preventing water hammer. Its requirements for water quality are not strict.