Triple Eccentric

Series SB63

Specifications

Triple Eccentric - Series SB63

Features & Benefits

-

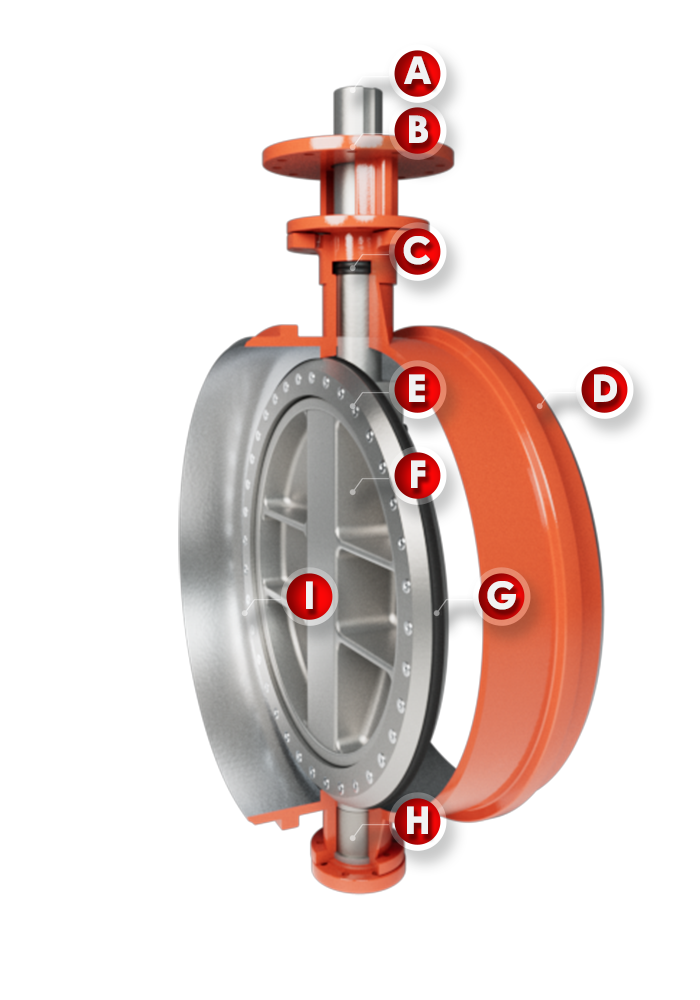

A. Stem Connection

The stem connection can be customized into different shapes (square or round+key)to connect the drive.

-

B. Top flange connection

Yoke under actuator can be selected, which alllows to install gear box, electric or pneumatic actuators accoridng to different standards.

-

C. Packing

PTFE (or reinforced graphite) packing material can effectively enhance the sealing performance of the stem. In order to reduce the openning & closing toque and make the operation more labor-saving, the bearing can be selected.

-

D. Retainer

The material of the retainer can be selected. (Remarks: The material of bolts & nuts is the same as the retainer) The retainer can well fix the position of the sealing ring in the disc, ensure the sealing performance, and provide the possibility of repairing and replacing the sealing ring.

-

E. Disc

Different materials of disc can be selected. Reinforcing ribs make it more firm and not easy to deform.

-

F. Body

One-piece structure has better pressure bearing capacity. And its material can be selected according to the medium.

-

G. Sealing Ring

Multi-layer or metal-to-metal sealing ring can be selected. At the same time, different materials can be selected to cope with different working conditions.

-

H. Stem

Bearings can be selected to reduce the stem torque. Different materials can be selected according to the working conditions.

-

I. Seat

The hard metal-to-metal sealing seat can be applied to high temperature and high pressure medium. The seat can be surfacing welding Stellite or other materials with high wear resistance and corrosion resistance.