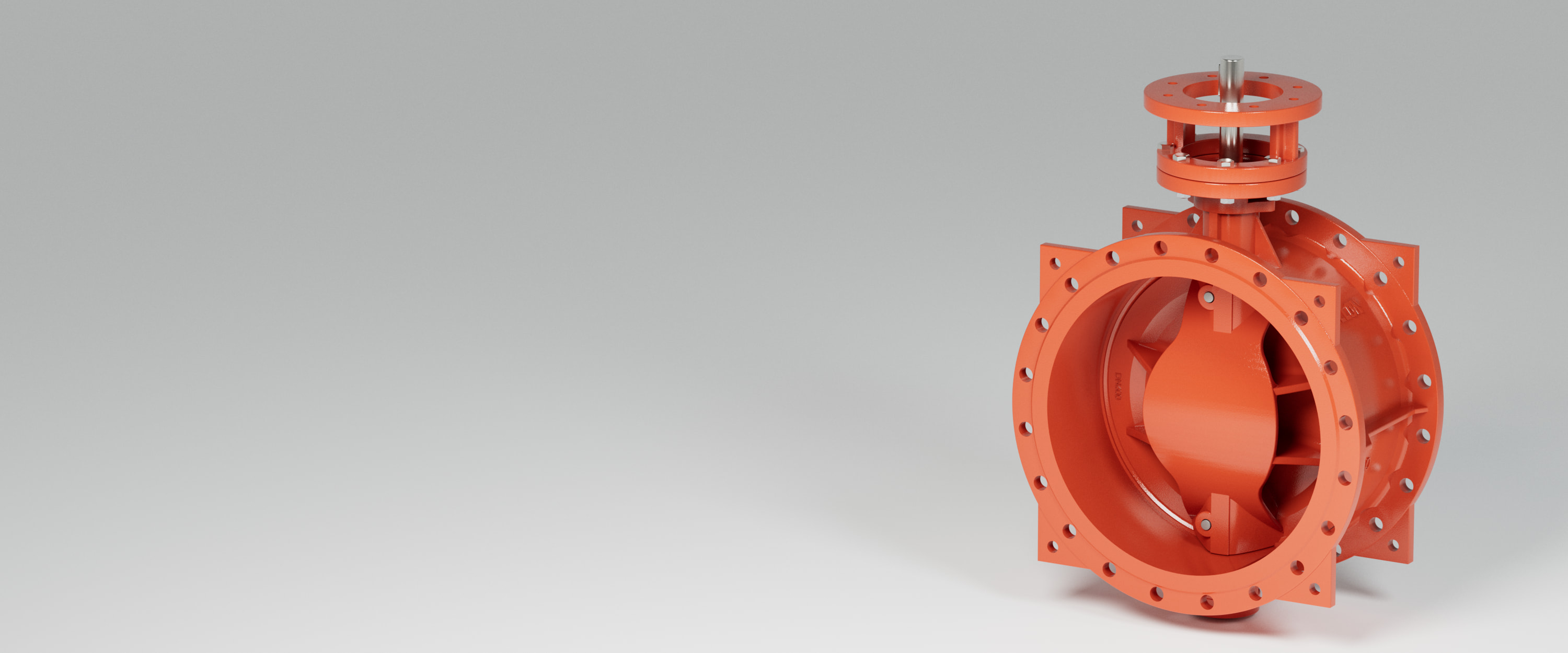

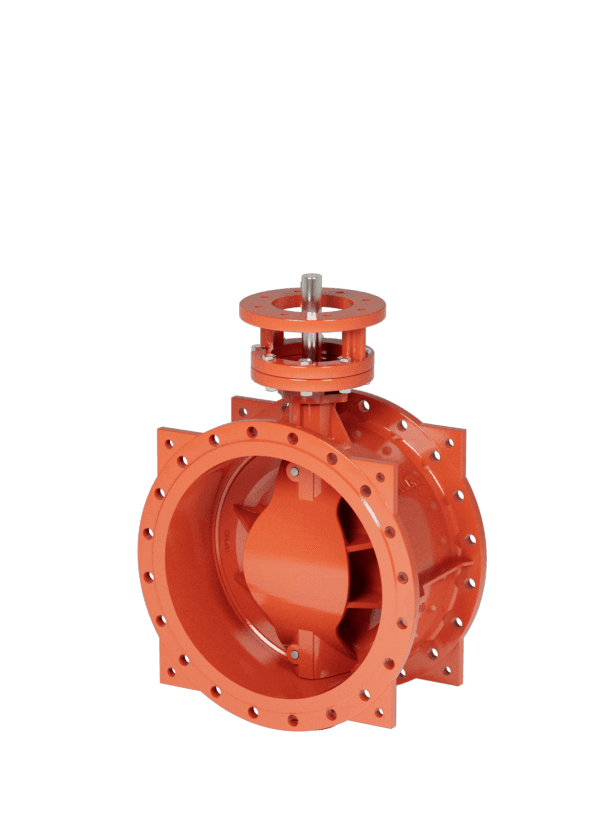

Double Eccentric

Series SB42

Specifications

Double Eccentric - Series SB42

Features & Benefits

-

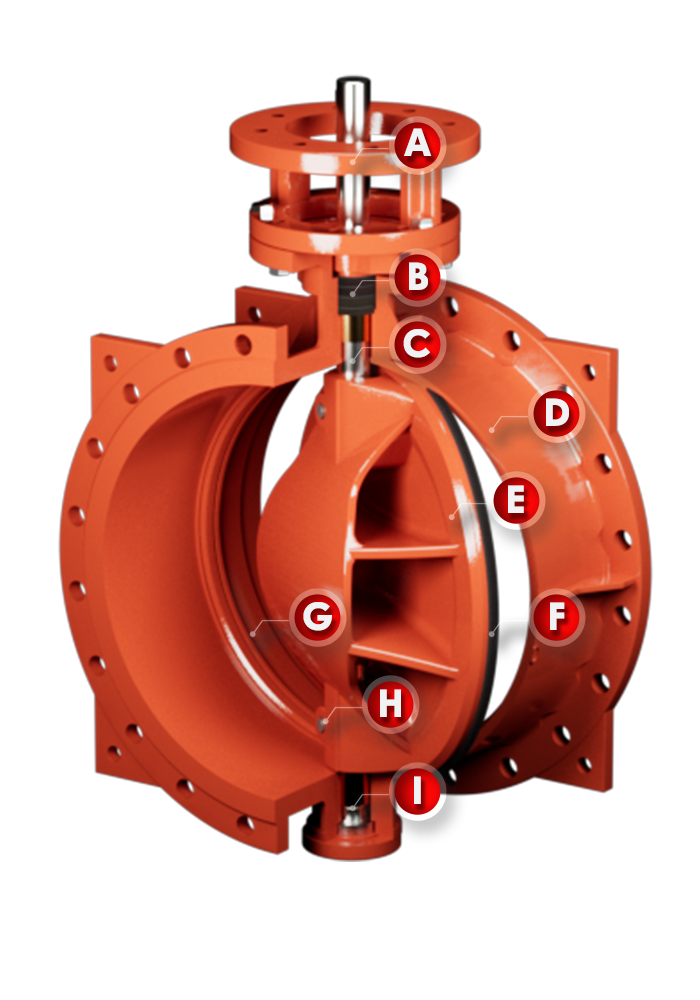

A. Top flange connection

Yoke under actuator can be selected, which alllows to install gear box, electric or pneumatic actuators accoridng to different standards.

-

B. Packing

Packing material PTFE (or reinforced graphite) can effectively enhance the sealing performance of the stem. In order to reduce the openning & closing toque and make the operation more labor-saving, the bearing can be selected.

-

C. Upper Stem

Bearings can be selected to reduce the stem torque. Different materials can be selected according to the working conditions.

-

D. Body

One-piece structure, more reliable reinforced body & better pressure bearing capacity. Its material can be selected according to the medium. Double eccentric structure reduces the opening & closing torque, reduces wear, improves the service life of the seat, and greatly reduces the degree of scratching. Different face-to-face dimensions can be selected. The coating of the body is epoxy powder with the thickness of more than 250 microns.

-

E. Disc

Different types of disc can be selected according to the DN and PN. The disc has higher strength and is not easy to deform. The hollow structure in the middle of the turtle back makes the water flow smooth and the resistance is small when the valve is opened. More than DN600 are suitable for turtle back disc. The surface of the disc is painted by epoxy powder, which has better anti-corrosion performance. Stainless steel disc can be also selected.

-

F. Sealing Ring

It is replaceable and its material can be adapted to the medium. L-shaped or T-shaped sealing ring is more firmly fixed.

-

G. Seat

The surface of seat can be welded with stainless steel to increase the wear resistance and service life, ensure the close fit with disc and achieve zero leakage.

-

H. Pin

According to different diameters, different positions will be designed on the disc, with different numbers of pins nailed to firmly connect with the valve stem, ensuring synchronous rotation of the disc and stem.

-

I. Lower stem

Bearings can be selected to reduce the stem torque. Different materials can be selected according to the working conditions.